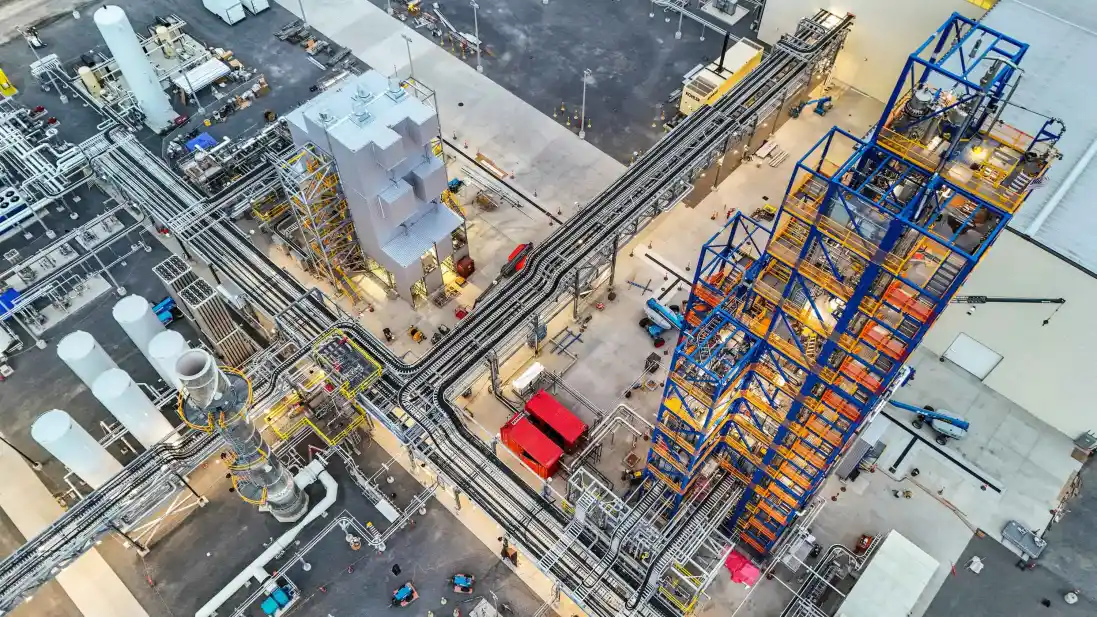

Battery materials startup Sila officially began operations Tuesday at its new facility in Moses Lake, Washington, marking the opening of the first large-scale silicon anode factory in the West. Initially, the plant will produce enough material to power 20,000 to 50,000 electric vehicles (EVs), with future expansion capacity for up to 2.5 million vehicles.

Silicon anodes can boost lithium-ion battery energy density by up to 50%, a breakthrough that Sila has been pursuing for 14 years. Co-founder and CEO Gene Berdichevsky said the new factory gives the U.S. a crucial opportunity in the global race for battery dominance.

Sila has secured supply agreements with Panasonic and Mercedes, while also providing material to drone, satellite, and consumer electronics makers. Unlike graphite-based anodes, dominated by Chinese suppliers, Sila’s silicon anodes could offer faster charging, lower costs, and a domestic supply chain advantage.

Washington State was chosen for its mix of cheap hydropower, available land, and local raw material suppliers. The factory was financed partly by a $375 million funding round raised last year.

Related: Fourth Power’s “Liquid Metal Batteries” Could Make Green Energy Cheaper Than Gas

Competitors like Group14 and Amprius are also advancing silicon anode technology, but Sila’s Moses Lake facility is the first at automotive production scale in the U.S. If demand grows, Sila plans to expand within the U.S. and eventually into Europe and Asia.

Berdichevsky emphasized the importance of domestic production: “As a country, if you don’t make stuff, where’s your pride going to come from? … We can never fall behind again.”